-

공작기계.금속.플라스틱.목재.가공

공작기계.금속.플라스틱.목재.가공

-

식품.화학.포장.물류운반

-

계측.시험.FA자동화.로봇.전기.전자.통신

계측.시험.FA자동화.로봇.전기.전자.통신

-

건설중장비.농기계.환경.플랜트

-

공구.산업안전.부품.소재.소모재

공구.산업안전.부품.소재.소모재

-

유공압.냉난방.냉동.공조.유분입체

유공압.냉난방.냉동.공조.유분입체

-

일반산업기계.기타

ET Trans Power Cylinder (1)

As a hydraulic &;pneumatic one-type cylinder,ET Trans Power Cylinder

is a high-speed cylinder without energy wasting.

Patented technology.

▶Life Test 10,000,000Cycle / Over 31,536,000Cycle work results

(1year = 31,536,000sec)

High productivity and cost saving

* About 20% of productivity is increased

* Fast approach and returning speed (4ton approach test /200mm/0.5sec)

* Energy waste

* Approach and returning use only minimum force necessary for movement

* Lowest operating pressure 0.5Bar

Easy applying and maintenance

* nstallation - Tightening 6 ~12 bolts is all

* Piping - Very simple with air hose piping

* Electricity - No electric power wiring / Only signal power is required

* Movement arranging - Simple or no need

* Control of working force - Adjust air pressure

* Checking for working force - Check the pressure inside cylinder

Eco - friendly

* Minimizes consumption of energy

* No need hydraulic power Unit &;hydraulic piping

* Area for installing reduces and there’s no pump noise and

* piping,compact and clean with no worry about leaking

L Type

Good Price,Best Quality

For Your Best Partner

Applied works

Punching I Stamping I Notching I Shearing

Marking I Coining I Upsetting&;Swaging

Squeezing I Straightening I Bending

Spot Welding I Projection Welding

Clamping I Holding I Press Fitting

Peening

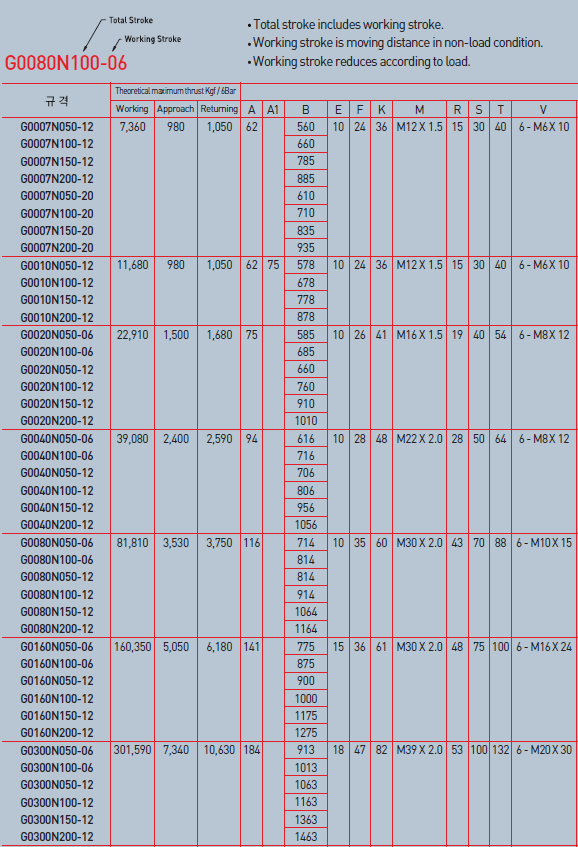

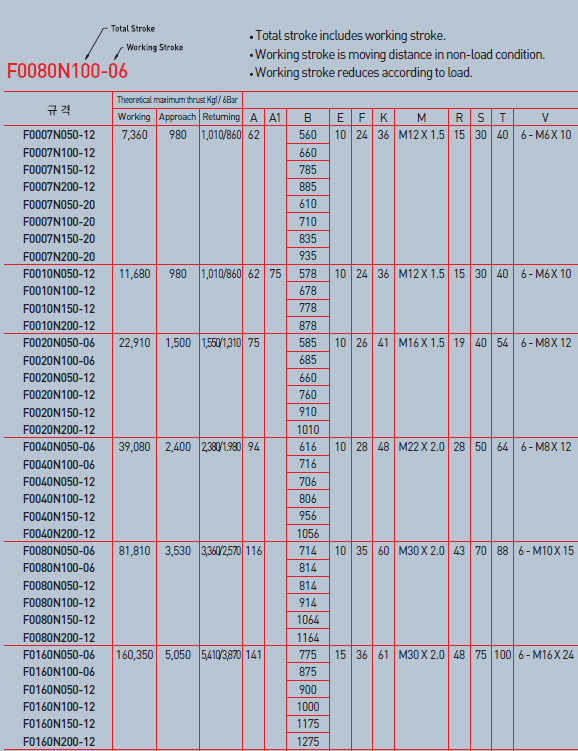

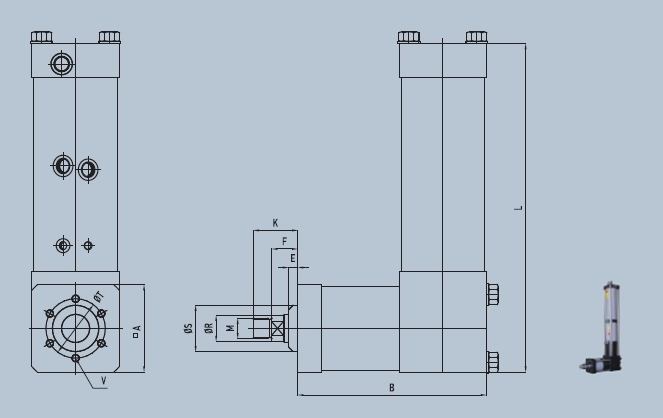

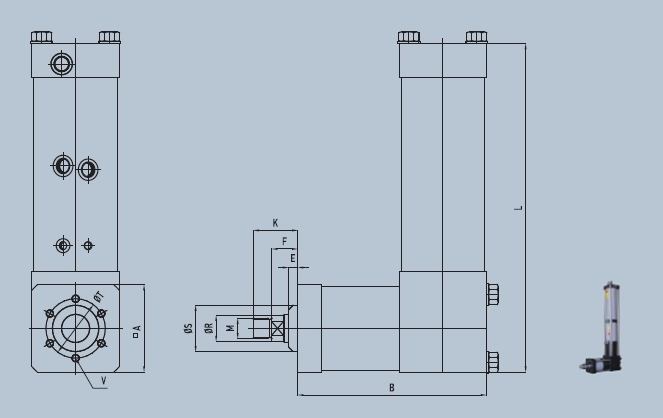

Manufacturing range

* 0.2~200ton Power

* 80mm,Work stroke

* 400mm,Entire stroke

* Entire stroke = Approach St + work St

* Returning is the same as entire stroke

Cylinders manufactured

* Standard type (G,F)

* Compact type (U)

* Horizontal type (L)

* Working stroke adjustment type(W)

* Total stroke adjustment type (T)

* Separated type

* Other special type

U Type

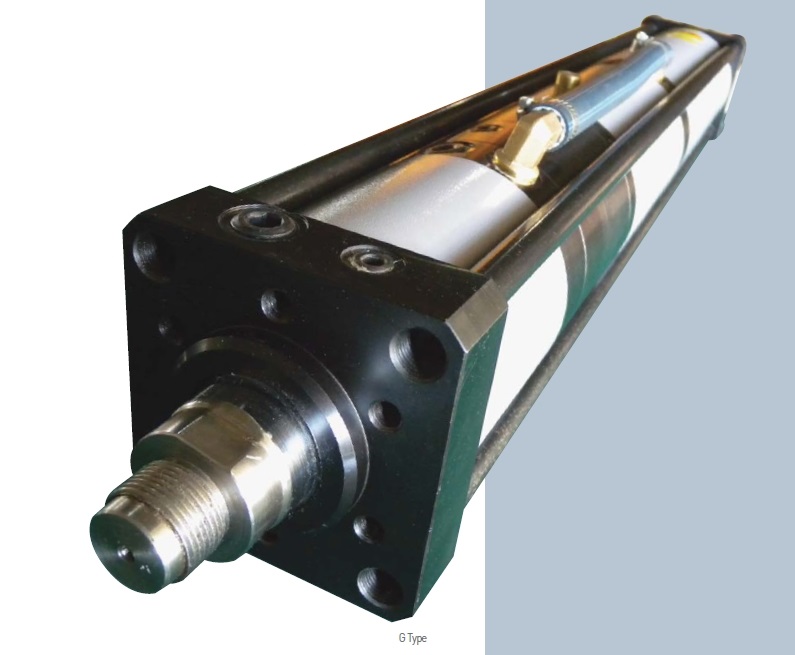

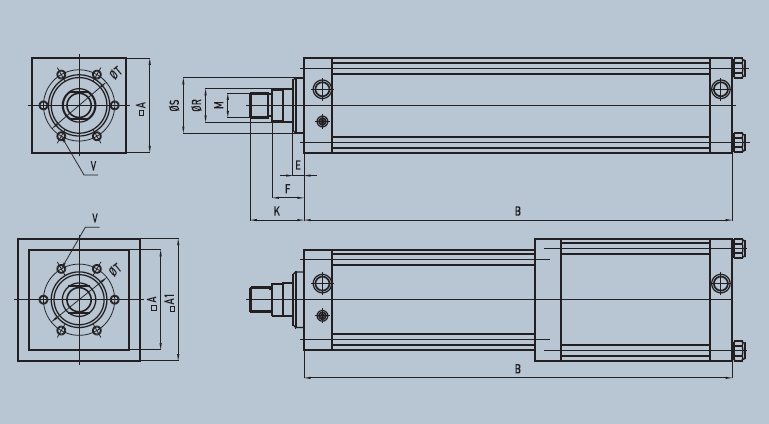

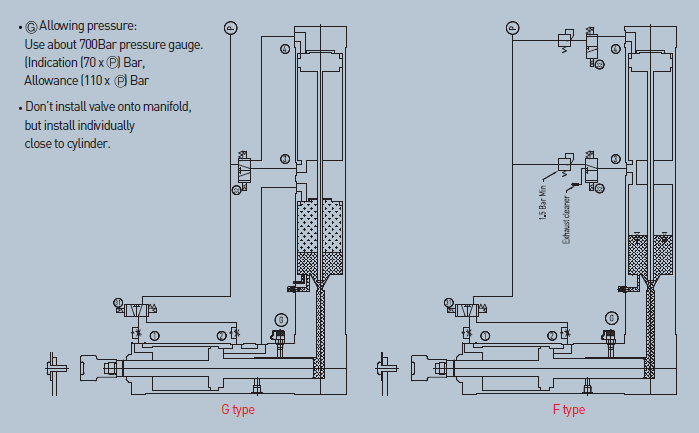

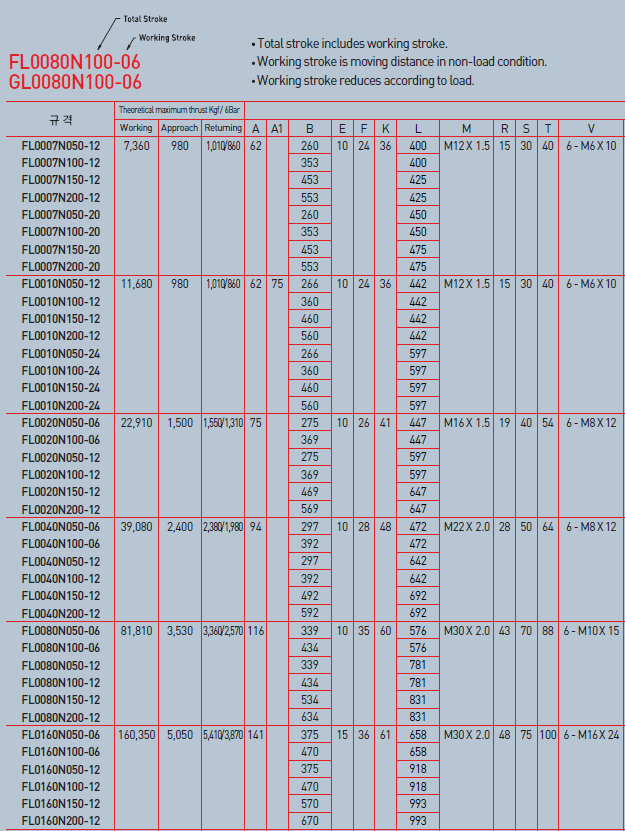

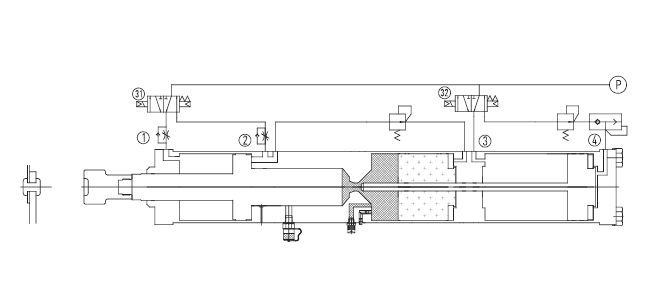

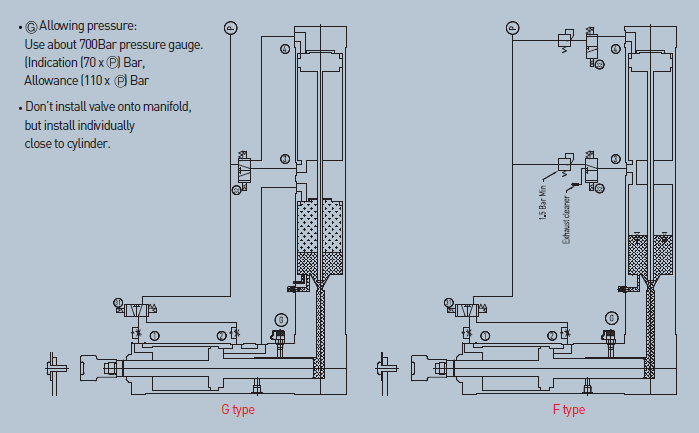

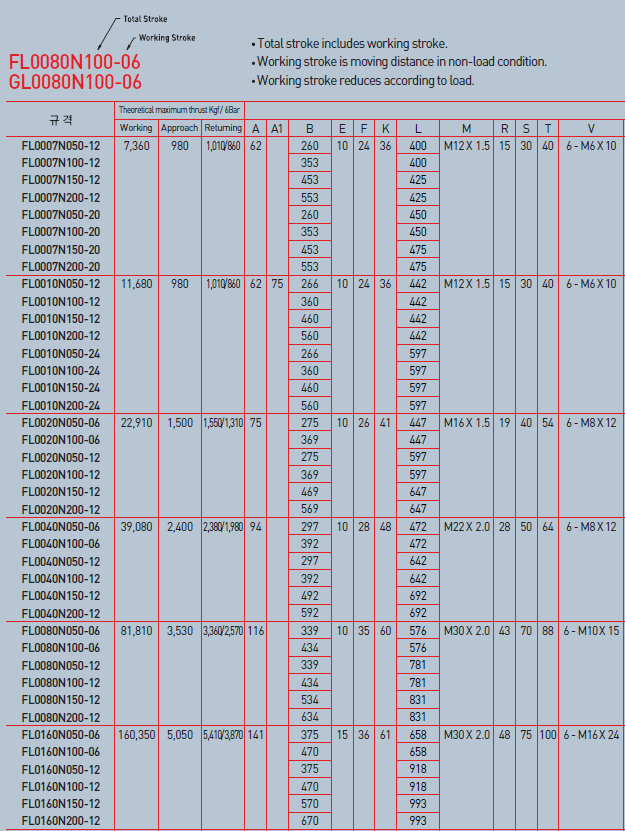

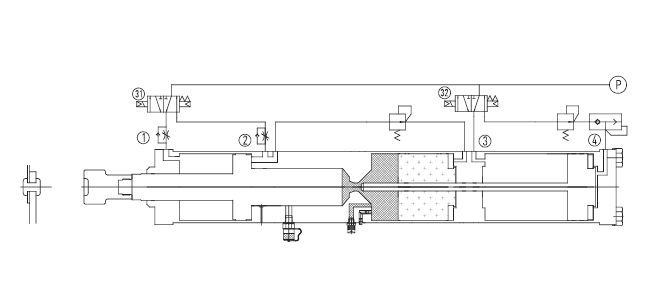

G Type Trans Power Cylinder 6Bar Series

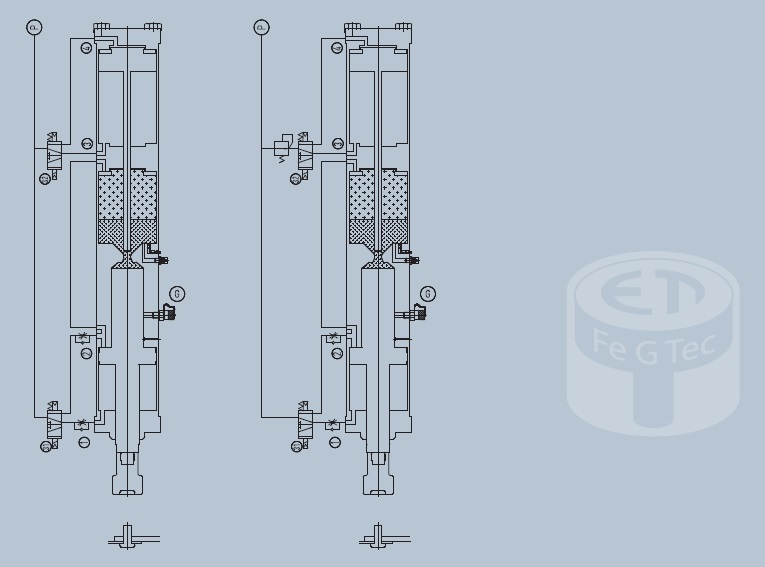

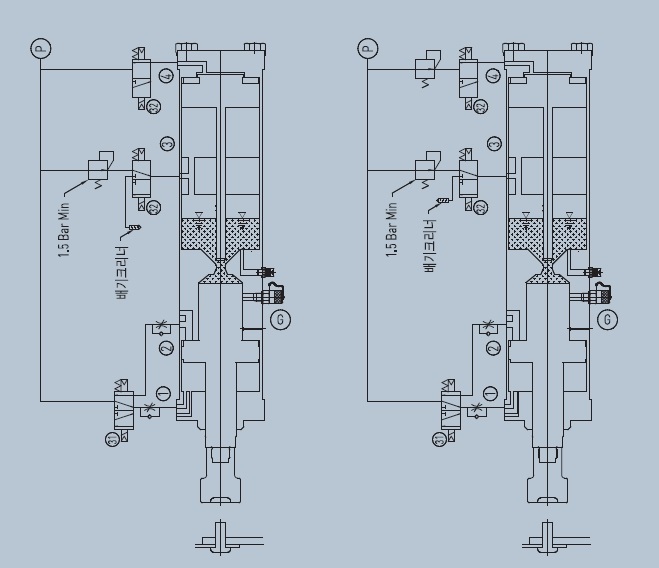

G type Basic circuit diagram

* G Allowing pressure:Use about 700Bar pressure gauge.

(Indication (70 x ) Bar,Allowance (110 x ) Bar

* Don’t install valve onto manifold,but install individually

close to cylinder.

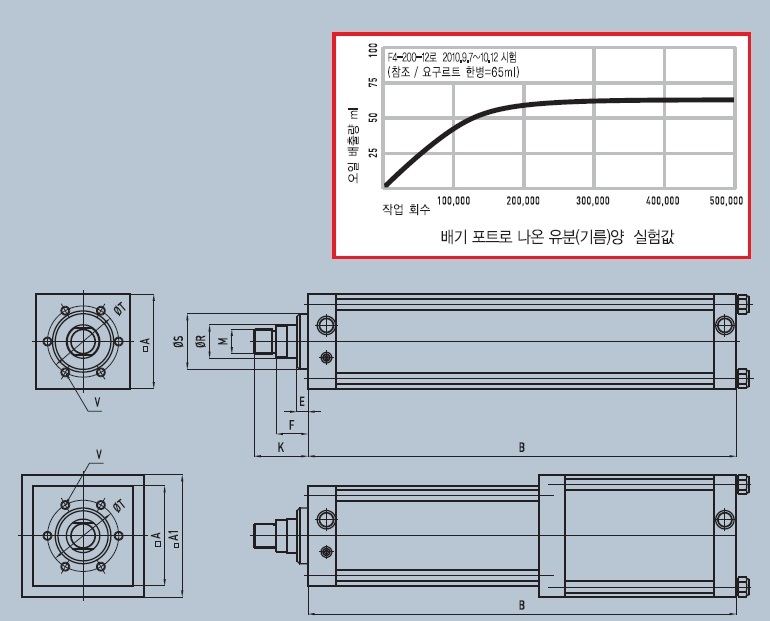

F Type Trans Power Cylinder 6Bar Series

#2 Pistonless Cylinder,Very Handy

Merits

* Cylinder life is extended compared with G Type

* Air penetrated into hydraulic fluid is naturally dissipated

* Control of cylinder is very convenient

* Replenishing of hydraulic fluid is easy

Consideration when applying

* F Type is applied only downward working

* Possibility oil mist in exhaust air

* #3 port exhaust cleaner is recommended

* working pose limitation(downward)

* Extend cylinder’s life

F type 기본 회로도

* G Allowing pressure:Use about 700Bar pressure gauge.

(Indication (70 x ) Bar,Allowance (110 x ) Bar

* Don’t install valve onto manifold,but install individually

close to cylinder.

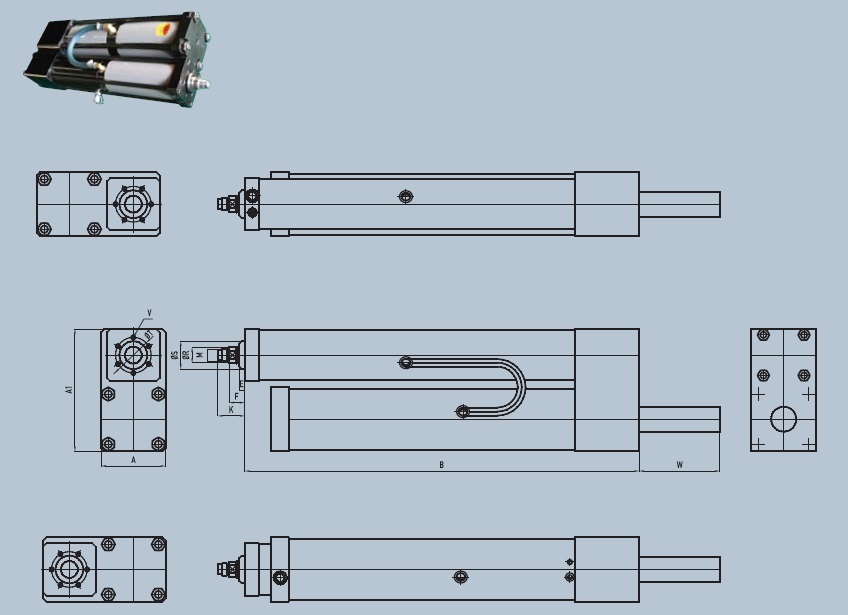

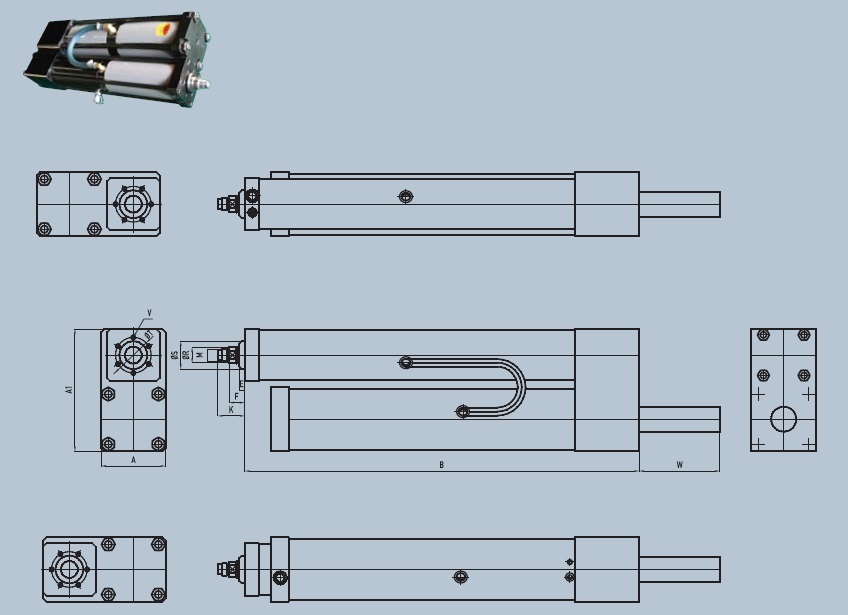

L Type Trans Power Cylinder 6Bar Series

For Horizontal Load

F(G)L type Basic circuit diagram

* G Allowing pressure:

Use about 700Bar pressure gauge.

(Indication (70 x ) Bar,

Allowance (110 x ) Bar

* Don’t install valve onto manifold,

but install individually

close to cylinder.

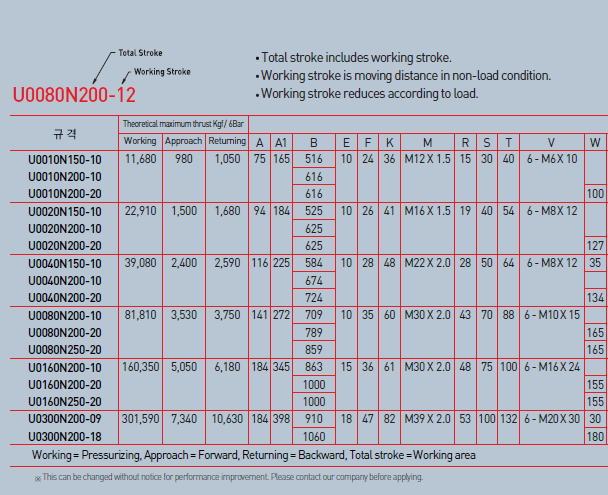

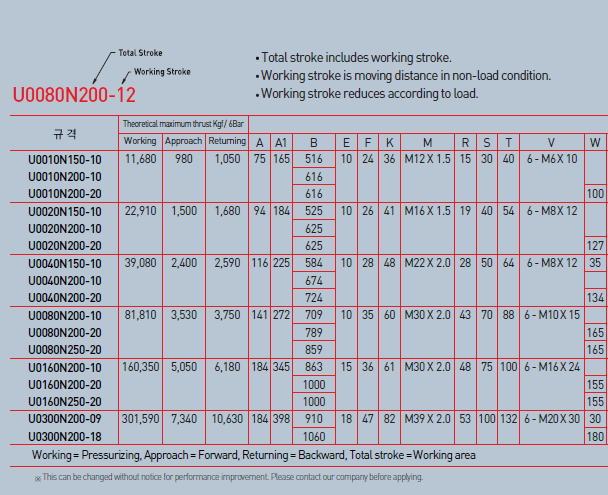

U Type Trans Power Cylinder 6Bar Series

Compact Type

* There’s no limit in working pose like G Type

* The speed decreases a little compared with G Type

* Available to apply the same as G Type

U type Basic circuit diagram

* G Allowing pressure:

Use about 700Bar pressure gauge.

(Indication (70 x ) Bar,

Allowance (110 x ) Bar

* Don’t install valve onto manifold,

but install individually

close to cylinder.

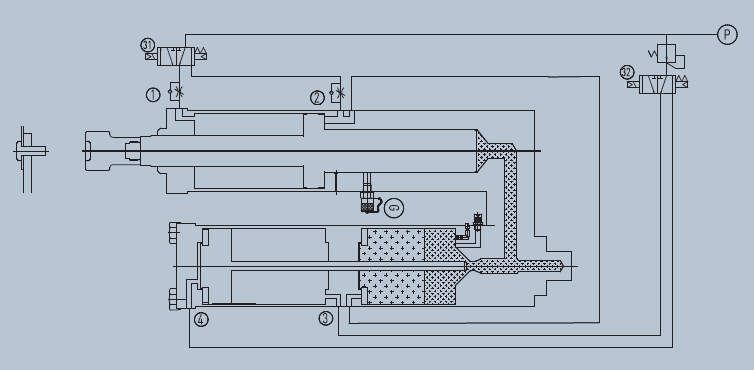

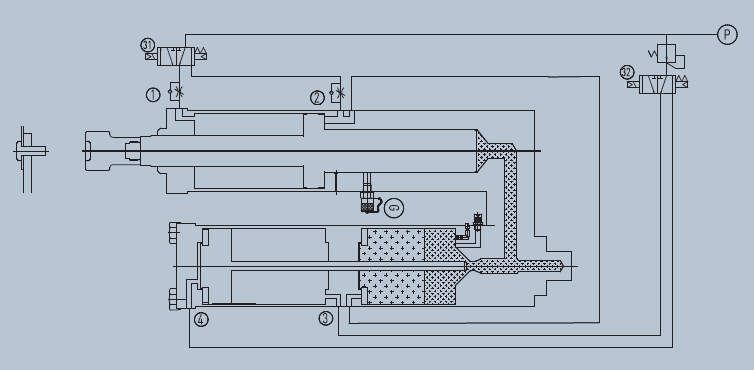

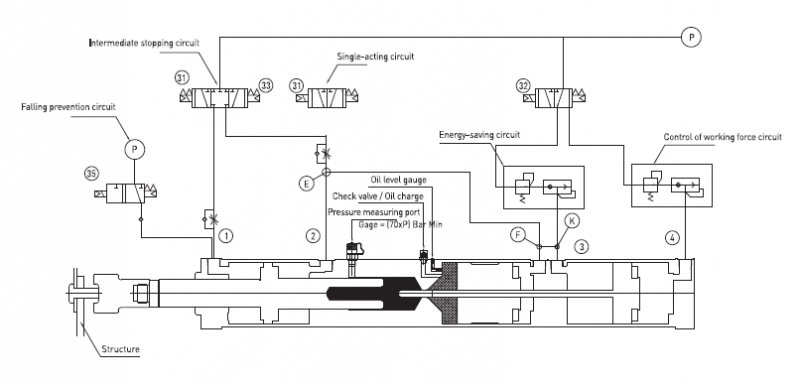

동작 설명

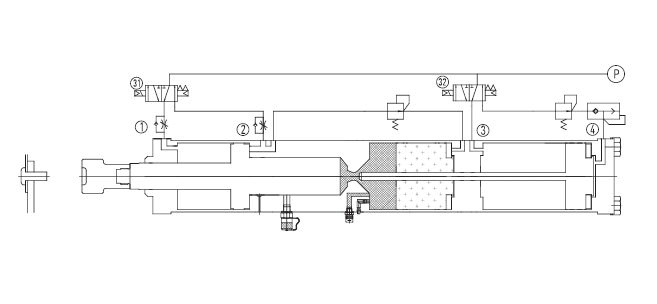

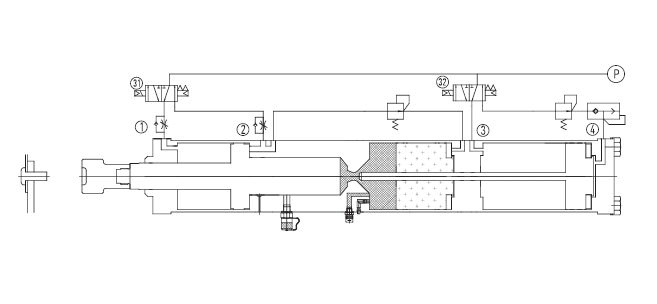

NO.1 Starting point

When supplying pressured air to cylinder,the working load

completely returns,locating at starting point. That is,the

pressured air is supplied to 1 ,3 port,and working load

returns as 2 ,4 port become in discharge status,

working’s being prepared with pressurizing piston is in

returned status,because solenoid 31,32 of direction

conversion valve are not applied with electric current.

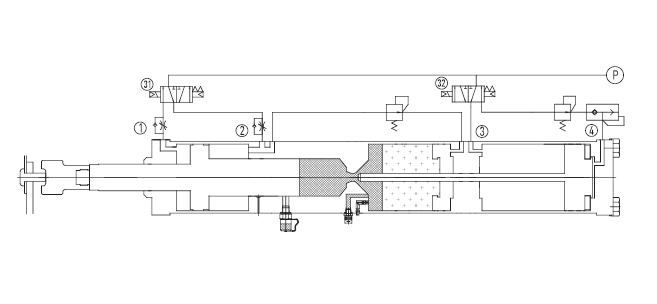

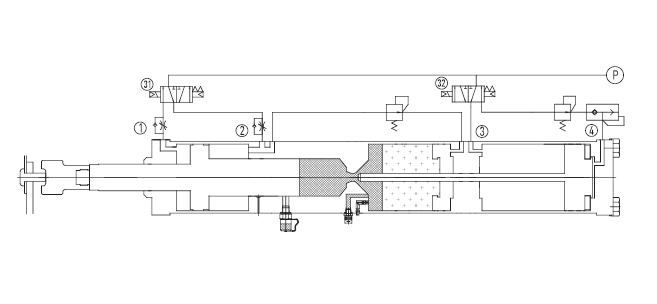

NO.2 Approach

When 31 solenoid of direction conversion valve is applied

with electric current in cylinder with being ready for

working at starting point as pressured air is supplied,the

valve converts and 1 port becomes discharge status,it

comes out in high speed until working load touches work

piece with pressured air being supplied to 2 port.

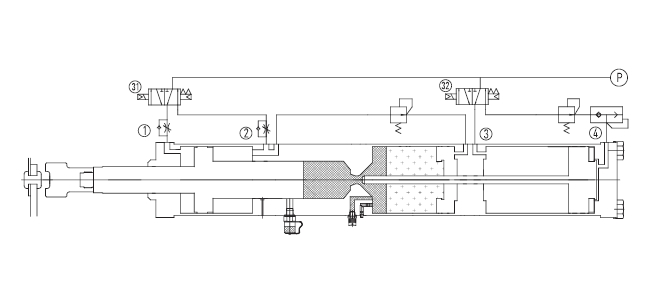

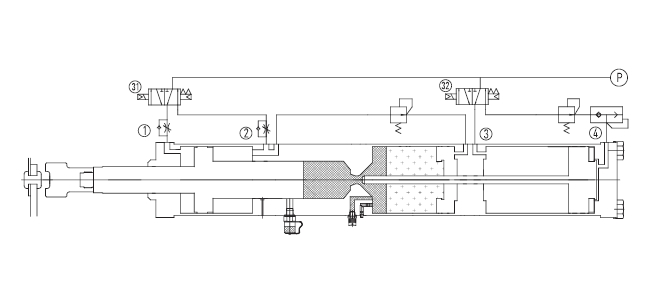

NO.3 Working

When solenoid 32 of direction conversion valve is

additionally applied with electric current in condition that

the tool installed on working load’s shelf,port 3 becomes

discharge status,the plunger is inserted into hole with

supply of pressured air to port 4 ,and high pressure

happens to working chamber,and molds with adding

necessary force to processing of work piece with

continuous progress of plunger.

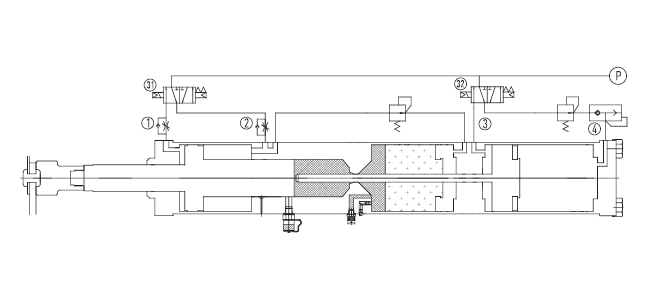

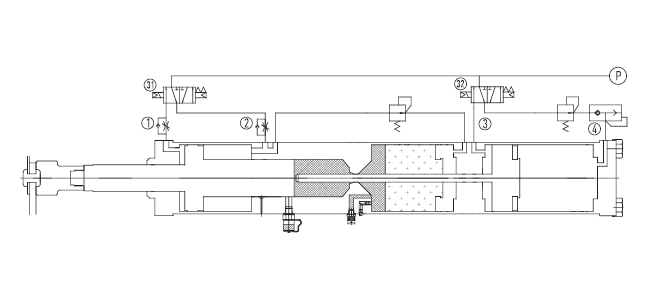

NO.4 Returning

When cutting off supply of electric current at solenoid 31 ,

32 of direction conversion valve in the cylinder that

working(molding) is completed,the valve returns by

spring,and the plunger in 2 ,4 port of cylinder comes out

of oil rout’s hole with pressured air supply to 1 ,3 port,

and when opening the working chamber,the working load

returns in high speed.

NO.5 Completion

When working load completely returns,the working is

completed and ready for next working.

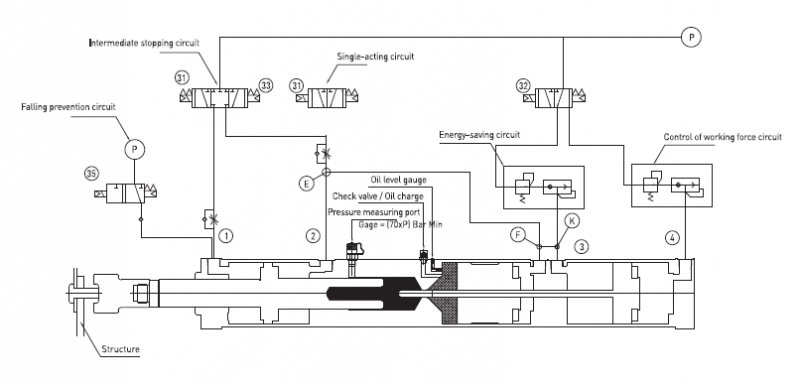

Trans Power Cylinder (2)

1. Remove section when using energy-saving circuit

2. Remove section when not using energy-saving circuit

3. Meter out speed adjustment is a must for port (Approach speed = Returning speed)

4. The circuit for falling prevention,energy saving,control of working force,intermediate stopping is optional in selecting

5. When using single-acting circuit instead of intermediate stopping circuit,it automatically returns when power is cut off

6. The control of process is available for Open Loop control using 2~3 timers

7.Certain control of process should control Close Loop with use of location detecting sensor and timers

Trans Power cylinder

1. The distance that working load can move is within total stroke.

2. Total Stroke = Approach St + Working St = Returning St

3. Working St is moving distance of load in non-load status,the actual

working St reduces according to the size of load(about 70% / 70%)

4. The structure that cylinder’s force works should be very strong.

5. Should use lubricated pressured air.

6. Should check cylinder in 500,000stroke working cycle,and do replenish of oil,deaeration,oil changing.

7. When abnormal vibration happens in cylinder and force is short,

you should make the approach stroke time long enough.

8. When working pressure is low,the oil is short or air is penetrated into oil(should replenish or change oil)

9. Pressure measuring gauge is indication (70 x ) Bar,over allowance (110x ) Bar

10. To protect tools and cylinder external compulsory stopper should be installed and you can’t use stopper at the end of stroke.

11. Recommendations

The valve which operates cylinder should not be installed on the same manifold,but install it around cylinder independently(prevent malfunction in fast working).

When cylinder is located on starting point,compose the circuit that air is supplied to port and make this circuit not be interrupted even when the load of cylinder is moved(required for oil control).

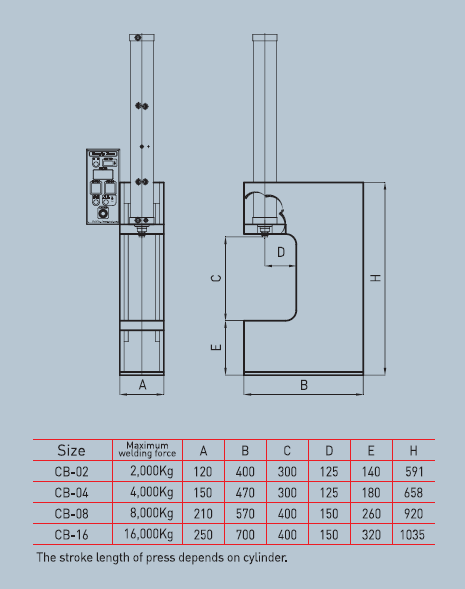

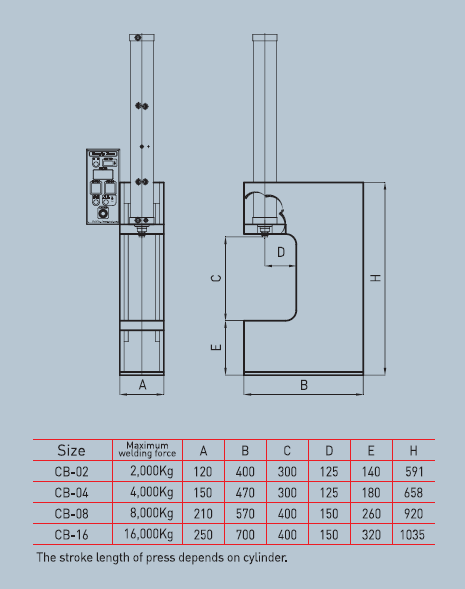

C Frame Bench Press

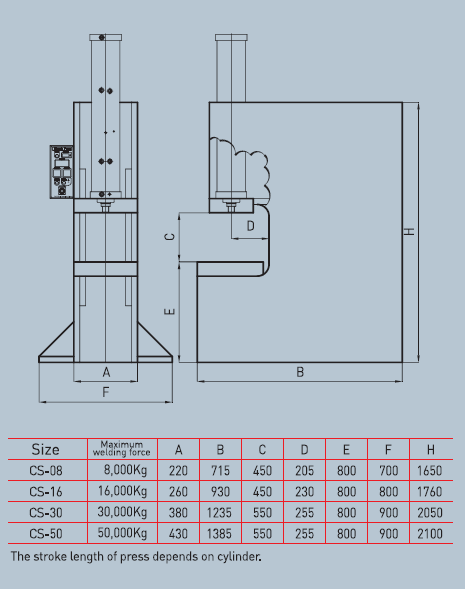

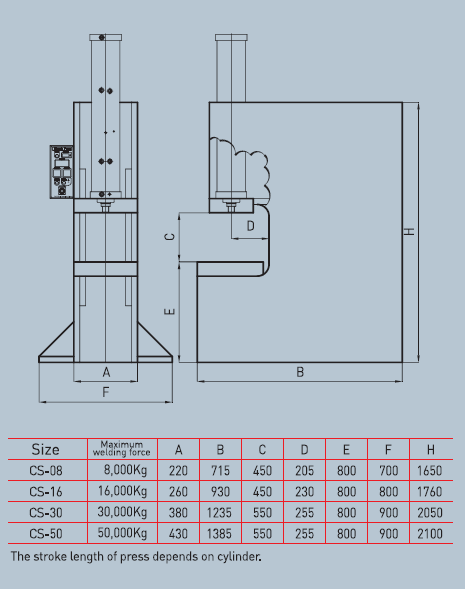

C Frame Stand Press

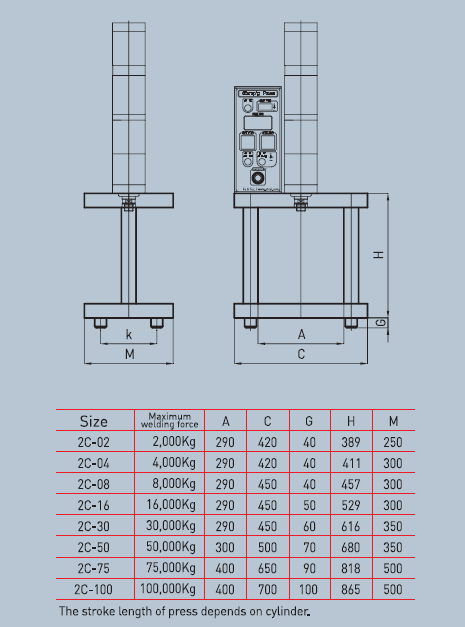

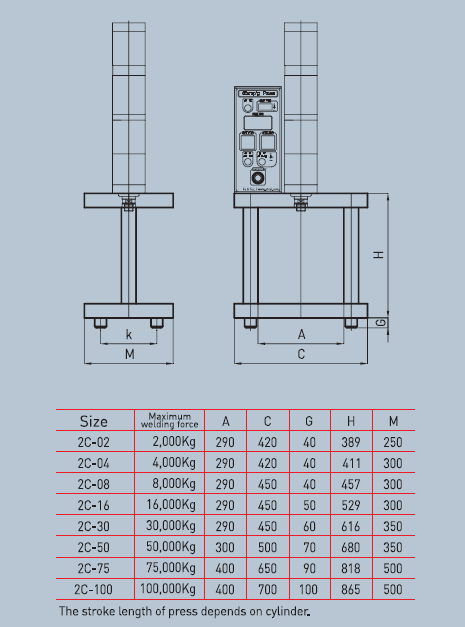

2 Column Press

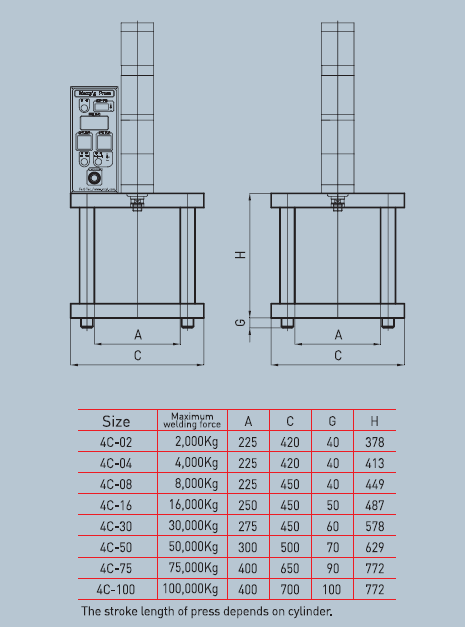

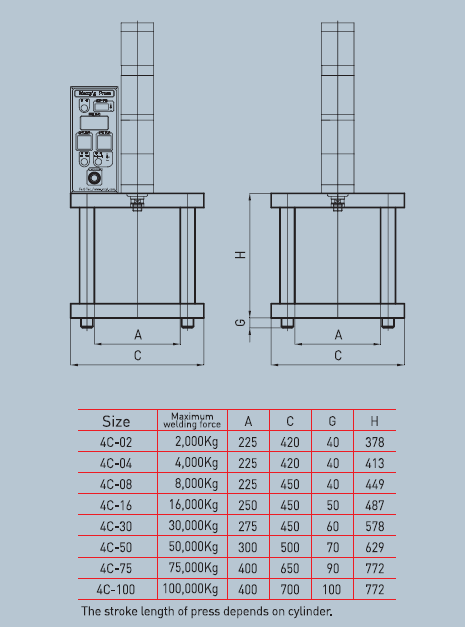

4 Column Press

| 회사명 | 에프이지텍(FEG) | 핸드폰번호 | 010-3850-8853 |

| 전화번호 | 053-584-8853 | 홈페이지 | http://www.etcyl.com |

| 담당 | 대표 김기찬 | 이메일 | gc2049@daum.net |

| 주소 | 대구 달서구 성서로24길 29-18 (월암동) | ||